The Quality Test For Sex Dolls

Whether you have used a sex doll or not, I am sure you can imagine how sex dolls can be used. Users often have significant skin contact with sex dolls. For certain customers, sex dolls are not just sexual toys but special companions. As a product that these users will have prolonged contact with, quality and safety are of utmost concern. This blog will take you through the quality control of sex dolls, covering materials, skeletal structures, and other functional tests to make you rest assured about using sex dolls.

All For Your Safety

Safety always comes first. Currently, the most popular sex dolls on the market are made of TPE material due to its high cost-effectiveness. What’s more, TPE sex dolls with elastic touch oral capabilities feel as good as silicone sex dolls.

However, TPE material is a synthetic chemical material. TPE sex dolls can pose various risks, if the TPE material used to make sex dolls can not meet the qualified standard. It’s reported countless examples exist that sex dolls made with inferior materials can cause skin irritation. Plus, the lifespan of such low-quality dolls is short, for it can result in surface cracks, loose skeletons, and other problems after just a few uses. No one expects to receive such sex dolls at a high cost. Through rigorous testing, manufacturers can prevent such issues. The tested dolls should be free from harmful chemicals to ensure that every interaction is safe and enjoyable.

How Are Sex Dolls Tested?

Currently, there are two main types of sex dolls on the market: silicone sex dolls and TPE sex dolls. Silicone sex dolls have a relatively uniform material composition and better heat resistance than TPE, so this article will focus on the tests of TPE sex dolls.

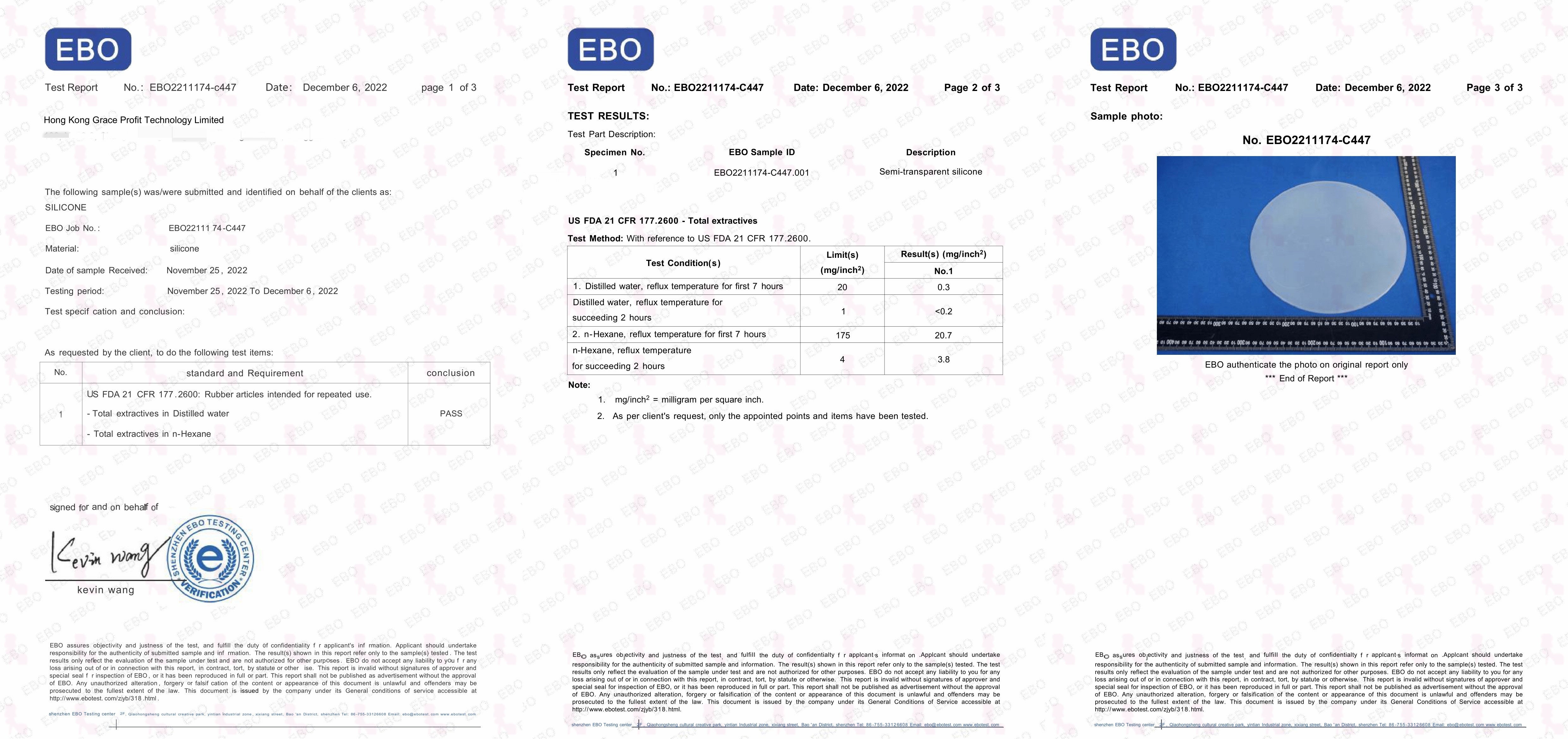

All of our sex dolls have official FDA certification, have passed the relevant requirements stipulated by the European Parliament and EU Directive 2009/48/EC, and have met CE certification specifications. You can shop with confidence here.

Check out our Quality Assurance.

TPE Material Safety and Durability Testing

Tensile Testing: This test can be used to know how much the material can stretch before breaking. It provides a good indication of how sex dolls handle different positions and pressures.

Tear Testing: A small sample of the material is torn, which helps manufacturers understand the material's durability against potential wear and tear.

Heat Resistance Testing: Sometimes, sex dolls are exposed to heat, whether from sunlight or other sources. This test ensures that the material won't melt or deform.

By conducting these tests, manufacturers can guarantee the safety and longevity of TPE sex dolls, ensuring a worry-free experience for every user.

The Importance of Low Allergenicity and Body Safety Materials

Many people may not consider this, as TPE materials generally do not cause allergies. However, there are no absolutes, and some individuals may experience allergic reactions to TPE materials. To prevent allergic reactions, it is recommended that those with a history of allergies to TPE materials avoid contact with this type of material. When purchasing products, you can choose alternative materials or look for TPE products labeled as 'hypoallergenic.' Additionally, you can conduct allergy tests in advance to confirm whether you are allergic to TPE materials and take appropriate precautions. Additionally, when buying products, choosing reputable brands and high-quality TPE material products is also an effective way to prevent allergic reactions.

The Temperature Resistance of TPE Materials

Sex dolls can be affected by extreme temperatures as many products. For example, a doll left in a cold room might feel unnaturally chilly, while one exposed to direct sunlight might become excessively hot or even deform.

The cool temperature has a significant impact on the mechanical performance and dimensional stability of TPE products. Generally speaking, the lower the cooling temperature, the better the mechanical performance and dimensional stability of TPE products. However, excessively low cooling temperatures may result in internal stress within the molded product, affecting its lifespan. Therefore, the optimal temperature range for TPE materials is -15°C to 60°C.

Testing the Skeletal Structure

The real life sex dolls are intricately tied to the quality of their skeletal structures. Each simulated pose of a sex doll relies on the support of a high-quality skeleton.

Flexibility Assessment

After production, every sex doll should undergo a test of joint flexibility. The flexibility of a sex doll's joints is crucial for ensuring that customers can comfortably explore various sexual positions with the doll. A good doll should, to some extent, mimic human flexibility.

The flexibility assessment focuses on the range of motion. Manufacturers rigorously test will test the various joints, including assessing the rotation angle of arm joints, the doll's ability to bend at the waist, and the naturalness of the bending degree. If a customer customizes articulated fingers, the supplier will also test each finger joint individually. The flexibility testing serves the dual purpose of checking the joints of the skeleton and ensuring that the TPE material's outer skin fits snugly and naturally with the skeleton.

Tests of the Optional Functions (for Advanced Features in Sex Dolls)

Electronic Components Testing

Advanced sex dolls are equipped with electronic components to provide additional features, such as voice capabilities and even heating elements.

These components require rigorous testing. This not only ensures their proper operation but also guarantees their safety. For instance, a short circuit in a heating element could pose a danger. Appropriate testing ensures that all electronic components function correctly and safely.

Ensure Waterproof Capability

Electronic products cannot be intruded by water. Some advanced dolls are designed to be waterproof, allowing for easy cleaning and even use in damp environments.

However, this waterproofing must be foolproof. I've come across instances where dolls claimed to be waterproof but had minor leaks, resulting in damage to the electronic components. Always ensure that the doll's waterproof claim is rigorously backed by testing.

Battery and Power Testing

Powering these advanced features are batteries. These batteries need to be long-lasting, safe, and efficient. Testing ensures that the batteries won't overheat, provide stable power, and won't unexpectedly run out.

The testing of sex dolls is aimed at ensuring that consumers can have a safe, high-quality, and durable experience with these products. From the choice of materials to the integrity of the structure and temperature resistance, every aspect undergoes stringent quality control.

Final Words

As the industry advances, testing methods continue to evolve, incorporating artificial intelligence, virtual reality, and real-time user feedback. Therefore, whether you are a potential buyer or simply interested in the subject, understanding that every premium sex doll undergoes a comprehensive series of tests can help ensure that you acquire a quality-assured sex doll.